Pre Engineered Metal Building

Pre-Engineered Metal Buildings (PEBs) are innovative, factory-built construction systems designed for strength, speed, and cost-efficiency. Unlike traditional construction, PEBs are manufactured using high-quality steel components that are pre-designed, pre-fabricated, and assembled on-site with minimal labor and time. These buildings are ideal for warehouses, industrial sheds, commercial spaces, showrooms, and large-scale infrastructure projects.

At Bansal Poles Limited, we specialize in delivering customized PEB structures that ensure structural integrity, superior load-bearing capacity, and minimal maintenance.

Why Bansal Poles Limited PEB?

With over 40 years of manufacturing experience in Pre-Engineered Metal Buildings, Bansal Poles Limited stands as a trusted name in the industry. As a leading PEB structure manufacturer, we specialize in delivering high-performance steel buildings tailored to meet the demands of industrial, commercial, and infrastructure projects.

Every PEB product, including our robust PEB sheds, undergoes a rigorous seven-tank galvanizing process to ensure superior corrosion resistance and exceptional durability—even in harsh weather conditions. This process enhances the longevity of our structures and makes them ideal for challenging environments.

We are also recognized as market leaders in the water tank manufacturing industry, offering reliable storage solutions across sectors. With an annual steel procurement of over 3,00,000 MT, we are fully equipped to meet high-volume production demands for both domestic and international projects.

Our success is backed by a team of experienced engineers, skilled technicians, and project management professionals. With a fully in-house facility for fabrication, testing, quality control, galvanizing, painting, logistics, and on-site installation, we ensure seamless execution from design to delivery.

Our Client list for other Divisions includes big and known contractor/EPC players in the country.

Benefits of PEB Structure

Let's explore the benefits of PEB structures

1. Experts guarantee - As per expert research, the PEB market in India is supposed to grow enormously in the next few years. It is recorded to be the most trending form of structure all over the world.

2. Time & cost-effective - Due to simultaneous work taking place in the factory and the site of construction, the PEB process has been a huge savior of money in the long run.

3. Quicker mode of construction - Technological advancements have made work easier and there is less load on the manpower. Its easily accessible to customers directly, creating a boom in the construction industry with growing convenience and popularity.

4. Recyclable - All materials used in the PEB structure are recyclable. In case a customer requires to get the prefabricated structure relocatable, it can easily be done, in addition to minimal amount of wastage involved.

5. Distinctive - Every building in the PEB structure is built differently from the other,in terms of design,creativity, pattern,etc.It caters to the customizable choice of the customers.>

6. Government's choice - It has been recorded as the go-to choice for a government's infrastructural campaign because of its quick results. Both private and public sectors are opting for PEB structure, a few examples include - industrial warehouses, storage, industrial shed,multi-story buildings,cold storage,etc.

7. Ever-increasing demand - With a rise in population,there has been a high demand for housing and then PEB comes to the rescue, being the fastest mode of construction structure possible.

8. Highly durable - Pre-engineered building structures have also widely been accepted because they provide a higher degree of durability,in case of earthquakes or any other natural calamity.

9. Acceptable for every structure - It is now used for all types of buildings such as low rise, medium-rise and skyscrapers,inIndia as well as all over the world.

10. Design Flexibility - No other technology,other than PEB technology provides the most required design flexibility for steel structures. They meet the customized design requirement of customers.

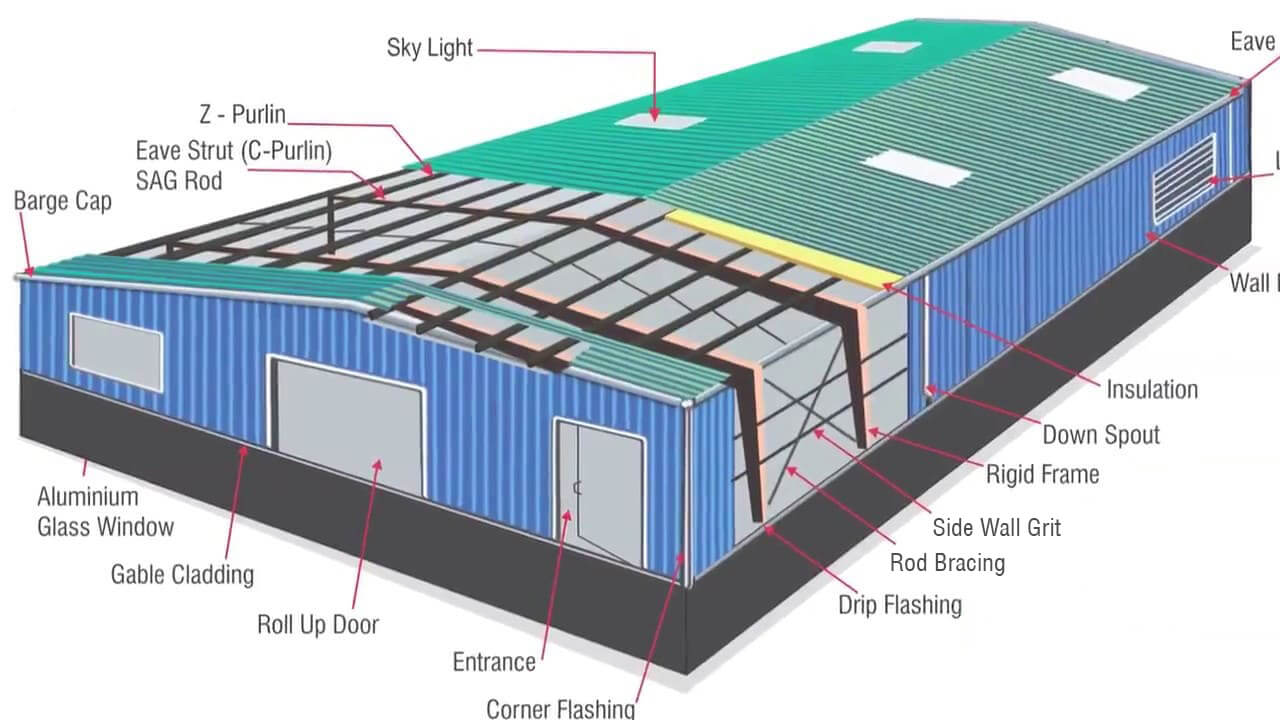

PEB Configuration and specification

Our pre engineered metal buildings are conforming following national and international standards

- Primary Standards: IS, AISC, MBMA (HR/Built-ups)

- Secondary (Cold form) IS 801 / AISI

- Roof live load: IS / MBMA

- Wind loads: IS / MBMA

- Manufacturing/Erection tolerances: MBMA

- Highly durable & galvanised material

- Conforms to IS 2062, ASTM 572 standards

Main Frames

Primary members are the main load carrying and support members of a pre-engineered building.

Crane Beams: Bansal Poles Limited's high-quality crane beams are uniquely designed to support members of different types of cranes, allowing swift unobstructed movement.

Mezzanine Systems: Bansal Poles Limited's superior standard mezzanine system consists of a profiled steel deck, mezzanine joists, built-up beams, and intermediate support columns.

Deck: Bansal Poles Limited manufactures advanced deck panels for creating composite slabs and floor beams, using innovative technology for durability and quality.

Trusses: Bansal Poles Limited offers a superior-quality built-in truss system fabricated with high-quality fixtures, easily customizable without the need for on-site welding.

Fascias: Bansal Poles Limited offers a diverse collection of high-quality, customisable fascias and canopies with a wide variety of designs- vertical, horizontal, or curved sheeting.

Canopies: Bansal Poles Limited offers a diverse range of high-quality canopies, including wall canopies designed for eaves, end walls, doors, and windows.

Bracing: Bansal Poles Limited manufactures a wide variety of angle bracing structures. Made through the hot-dip galvanising process, these structures can withstand extreme longitudinal forces.

Rafters: Bansal Poles Limited offers high-quality Rafters for effectively framing a roof. Available components: Common rafter, Plumb cut, Ridge board, Collar tie, etc.

Foundation Bolt: Bansal Poles Limited PEB uses a variety of foundation bolts, including Eye foundation bolts, L/J foundation bolts, bent foundation bolts, Rag foundation bolts, etc.

Secondary Members: Secondary structural framing refers to girts, purlins, base angles, eave struts, wind bracing, flange bracing, clips, and other structural parts.

Purlins & Girts: Bansal Poles Limited's purlins and girts are made of high-quality steel and used in columns, rafters, roofs, etc. providing support to roof sheeting and wall cladding.

C-Section: Bansal Poles Limited manufactures and supplies robust and durable C-sections, which are ideal for single, non-continuous span construction.

Eave Struts: Bansal Poles Limited has industry-leading expertise in making eave struts, located along the sidewall at the intersection of the roof and the exterior wall.

Open Web Joists: Bansal Poles Limited’s open web joists are lightweight steel trusses with parallel chords and a triangulated web system, ideal for floors, and roof deck support.

Curved Eaves: Bansal Poles Limited's curved eaves are made from color-coated steel after crimping and curving. These are durable and aesthetically pleasing structures.

Cable Bracing: Bansal Poles Limited manufactures robust cable bracing created by forging cables into rod terminals, securely fastened to structures using a hillside washer, nut washer, and nut.

Rod Bracing: Bansal Poles Limited's rod bracings are ASTM A-36 (or equivalent) quality standards approved and made with the highest quality raw materials.

SAG ROD: Bansal Poles Limited offers superior-quality SAG Rods, which can help prevent the sagging of an open-web steel joist.

Flange Bracing: Bansal Poles Limited's expert quality flange bracing provides unmatched external support for steel buildings by connecting to the rafter and purlin, column to girt.

Roofing & Cladding

Bansal Poles Limited’s top-quality roof and cladding structures feature a multilayered hot-dip galvanised coating, 0.5 mm/0.6 mm thickness, and 345 MPa minimum yield strength.

Standing Seam System: Bansal Poles Limited’s high-quality Standing Seam Panel System features a double lock standing seam for leakage-free protection in all weather conditions.

Cladding Wall: Bansal Poles Limited's superior quality cladding walls have been manufactured to provide maximum benefit to the customers.

Curved Cladding: Bansal Poles Limited's curved cladding sheets are designed from tested & verified raw materials using the latest technology.

Accessories: Bansal Poles Limited offers a broad range of building accessories in addition to main components.

Sliding Doors: Bansal Poles Limited's superior quality sliding doors are designed with the latest technology. Available in single-leaf & double-leaf designs.

Aluminium Windows: Bansal Poles Limited's aluminum windows are designed with utmost attention to detail for extra quality assurance. These windows come in double slides (size:1 m x 1 m)

Insulation: Bansal Poles Limited’s CFC-free, self-extinguishing insulation panels are made from high-pressure injected polyurethane foam and can be safely used for insulating a building.

Fixed Louvers: Bansal Poles Limited manufactures high-quality louvers consisting of an insect screen, hand crank, and blade adjustment lever.

Fasteners: Bansal Poles Limited’s fasteners are made of steel wire and EPDM-bonded washers to meet diverse infrastructural requirements. Available in plain carbon and stainless steel.

Ridge Ventilators: Bansal Poles Limited manufactures best-in-class ridge ventilators with utmost precision. Comes with a bird screen and a mechanically controlled damper.

Power Ventilators: Bansal Poles Limited's Power Ventilators have a low-profile 'C' whirlwind design, spun aluminum non-return shutter, and a single-piece base for effective rooftop ventilation even in calm weather.

Turbo Vent: Bansal Poles Limited offers top-tier turbo vents made from industrial-grade, corrosion-resistant aluminum. These lightweight, robust structures can endure extreme weather conditions.